Company History

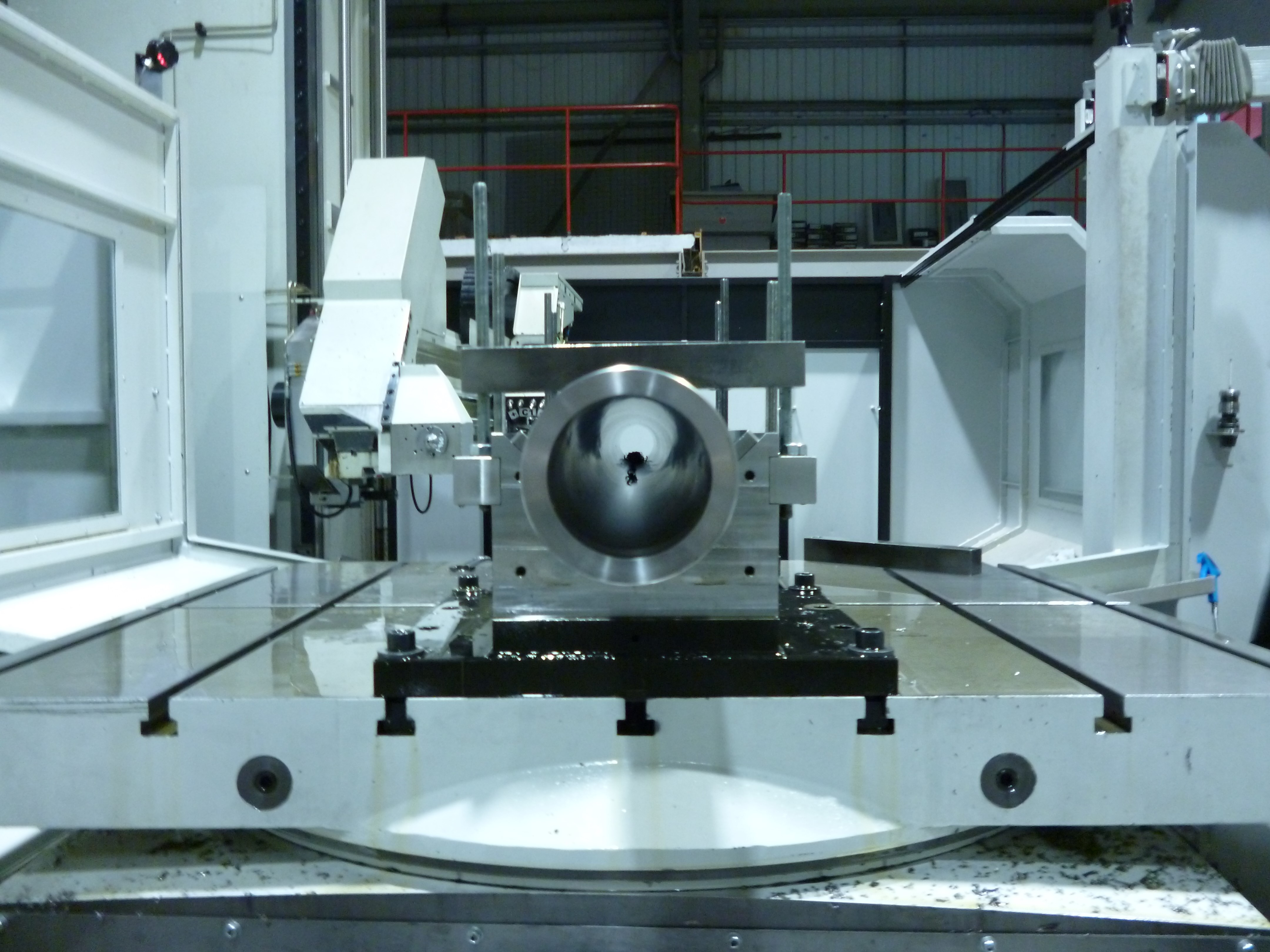

We knew from inception that our focus had to be achieving an exceptionally high quality of work to stand out in the commercially competitive environment of precision engineering. To reach such high standards Q-Mass needed to employ people, machinery and business processes capable of setting and continually improving these standards. The team that has been built and honed over the last 20 years has been key to our continued success and is something that Q-Mass continues to mould today. Customers have the confidence to place orders for the most complex of parts that the industry requires, knowing that they will be delivered correctly. The substantial investments Q-Mass has made in machinery and equipment have ensured that we have rapidly become one of the most capable precision machine shops in the industry. With multiple Mazak 5-axis turning centres, a TBT 5-axis deep hole drilling (Gun drilling) centre, 2 and 3 axis turning centres and EDM machines, most jobs can be tackled whether it is for one off prototypes or larger production runs. Our VAM license that we qualified for in 2014 has enabled the VAM services we can offer to our valued customers.

Where Our Products are Working

Leadership team

Paul Richards: Owner

Matthew Clark Sales Director

John Costello: Commercial Manager

Graeme Keenan: Operations Manager

Drew Oswald: Manufacturing Engineer

Mick McDonald: Production Manager

Our History

2006

Q-Mass starts with 3 machines and 4 employees.

2007

Due to continued growth and expansion we moved to a larger facility.

2008

First intake of apprentices. Wire Erosion added to capabilities.

2009

Gun drilling and honing added to capabilities.

2011

Manufacturing Engineering Team created. Spark Erosion added to capabilities.

2013

GMTK Accuracer HR1200 added to fleet of predominantly Mazak machines to extend our capabilities to 6m length and 0.8m diameter. (236”length x 32” dia.)

2014

Q-Mass qualifies for VAM.

2016

Q-Mass becomes 1st in the UK to qualify for brush copper plating on VAM threads. Q-Mass also adopts 5S Methodologies, and relocates to 5.5 acre facility in East Kilbride.

2021

MOD declare Q-Mass ‘Essential Workers’ to allow us to continue to supply them critical components.

2023

Purchase of Mazak Nexus 200 machine purely for internal training.

Join Our Team

We are continuously looking to expand and develop our Manufacturing, Engineering, Commercial, Finance and Sales Teams.

If you would like to join our team then please send your CV to: jobs@q-mass.co.uk or fill out the form below.